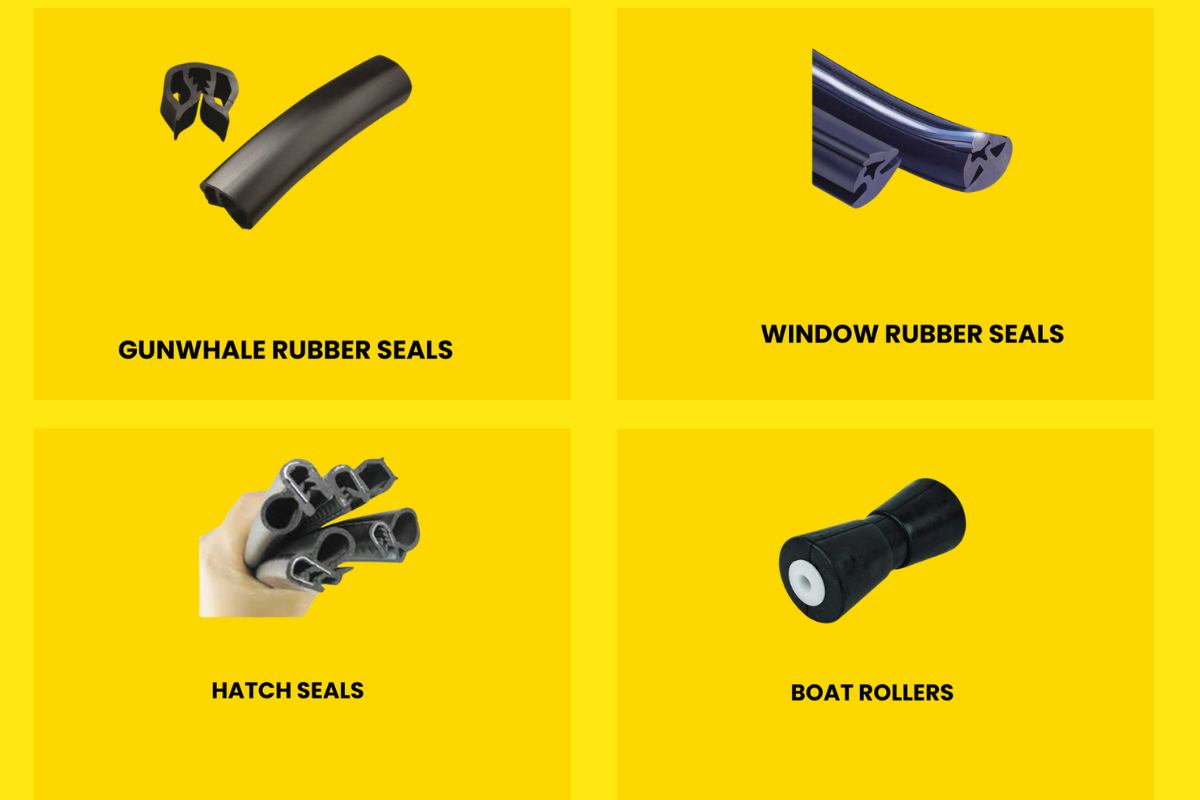

In the automotive and marine industries, rubber seals are vital for protecting vehicles and boats against the elements, vibrations, and operational wear. Whether it’s a car, truck, or marine vessel, high-performance rubber seals like hatch seals, window rubber seals, and gunwale rubber seals are engineered with advanced materials to ensure long-lasting durability, safety, and comfort.

The Role of Hatch Seals, Window Rubber Seals, and Gunwale Seals

Each type of seal serves a specific function, and their performance directly affects a vehicle’s or vessel’s efficiency and longevity:

Hatch Seals

Hatch seals are used around access panels, tool compartments, and cargo spaces in both vehicles and boats. These seals provide:

- Watertight protection against moisture, rain, and washdowns

- Dust and noise resistance in storage compartments

- Thermal insulation for temperature-sensitive areas

High-quality hatch seals are made from EPDM or neoprene rubber to withstand constant flexing, compression, and harsh environments.

Window Rubber Seals

Used around windshields, side windows, and rear windows, these seals:

- Prevent water and air leaks

- Reduce road noise and vibrations

- Improve energy efficiency in vehicle climate control

Modern window seals are engineered to fit complex contours while maintaining elasticity and UV resistance, ensuring a tight, long-lasting seal.

Gunwale Rubber Seals

Commonly found in marine applications, gunwale rubber seals protect the edges of boats and marine vehicles. They:

- Provide cushioning to absorb impact

- Prevent chipping and cracking at the hull edges

- Resist saltwater, UV, and temperature extremes

Gunwale seals often combine durable rubber with flexible construction to offer both shock absorption and protection in rough marine conditions.

The Science Behind Durable Rubber Compounds

These seals are typically made from specialized rubber compounds like:

- EPDM: Highly resistant to UV, ozone, and temperature changes—ideal for long-term outdoor exposure.

- Neoprene: Offers solid resistance to weathering and moderate chemical exposure.

- PVC/Nitrile Blends: Provide oil resistance, flexibility, and impact absorption.

Each material is chosen based on its chemical composition, performance under pressure, and longevity in its specific environment.

Precision Engineering and Performance

Using advanced extrusion and molding techniques, manufacturers can create rubber seals that:

- Fit precisely into vehicle and marine structures

- Maintain compression recovery for repeated use

- Offer noise-dampening and vibration-reducing benefits

The combination of materials science and precision design ensures these seals hold up under extreme conditions while offering maximum protection.

Choose Rubber Bits & Industrial Conveyors for Trusted Rubber Sealing Solutions

At Rubber Bits & Industrial Conveyors, we supply premium-grade hatch seals, window rubber seals, and gunwale rubber seals built to perform in tough New Zealand conditions. With decades of experience in industrial and marine rubber solutions, we provide custom-fitted, durable sealing products for automotive and marine applications.

Whether you need replacement seals or custom manufacturing, our team delivers quality, reliability, and expert support.

Get in touch with us today to learn more or request a quote.